Rubber and silicone compounds of consistently high quality

Gummiwerk KRAIBURG not only place special emphasis on extensive specialist knowledge and competence, but also on state-of-the-art testing technology for rubber and silicone compounds.

How does Gummiwerk KRAIBURG ensure excellent rubber compound quality?

Consistently high quality plays a key role. The correct choice and implementation of suitable testing and examination methods plays a decisive role in this respect. To meet the increasing demands on quality, we offer our customers modern testing technology which is constantly being optimized. This is also underlined by our regular internal and external audits. As well as our certifications.

Consistent quality

Our management system is regularly certified according to the following standards:

Did you know?

Rubber is not a material in the conventional sense, but a basic material. Many additives are added to this basic material before vulcanization. In addition to the basic material, all rubber compounds contain fillers, plasticizers, processing aids, antioxidants, or pigments. Thus, an elastomer compound consists of 10 to 20 components on average.

What makes the rubber compound quality at Gummiwerk KRAIBURG special?

The quality of rubber and silicone compounds is determined by many influencing variables. From the quality of the raw materials to the process technology used in production. But also, the reliability and experience of our long-standing employees play a key role in the high quality of our rubber and silicone compounds.

Furthermore, Gummiwerk KRAIBURG tests all raw materials for REACH conformity and uses – as far as possible – only harmless substances. In this way our products make a decisive contribution to sustainability.

Modern, efficient test methods, well-founded tests and their correct evaluation lead to the findings that enable the optimization and further development of compound formulations.

How does Gummiwerk KRAIBURG test its rubber compound quality?

The tests and test procedures of Gummiwerk KRAIBURG are based on DIN (Deutsches Institut für Normung e.V.), DIN ISO and DIN EN ISO. Test methods of the American Society for Testing and Materials (ASTM) are also applied, as well as tests according to individual OEM specifications.

In addition, we have our own test procedures, as the corresponding test characteristics are not described in any standard.

Overview of the most important test methods and equipment

Physical and chemical tests

- Thermal analysis

- Surface measurement

- Particle size distribution

- Cleveland flash point test

- Density measurement

- FTIR spectroscopy and many more

Physical and technical testing

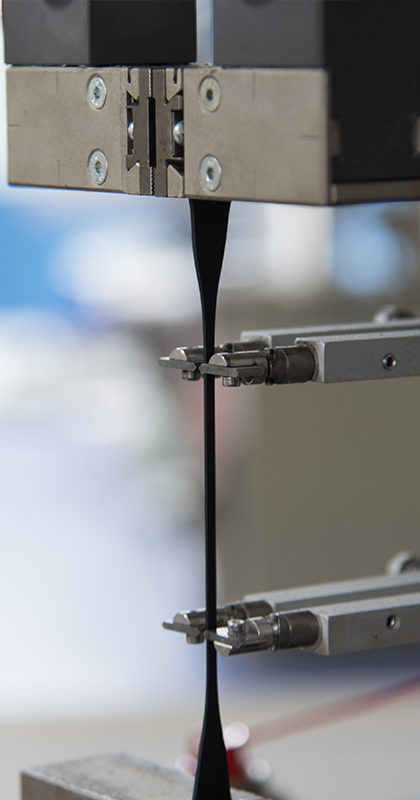

- Universal test machine for tear strength, elongation and tensile stress

- Hardness tester

- Rebound resilience test

- Ozone cabinets for determining resistance

- Abrasion test

- Compression relaxation

Rheology

- Mooney viscometer for viscosity, scorching behavior and relaxation behavior

- Curemeter for the cross-linking behavior of the compound

Processing behavior and vulcanization

- Rheovulk parameters

- Rubber Process Analyzer (RPA)

High testing quality in the laboratory at Gummiwerk KRAIBURG

In order to guarantee that our test results are valid and usable, our laboratory regularly participates in so-called round robin tests and achieves very good to good quality. The test quality of our laboratory is ascertained by independent institutions with the help of such tests. Here, an identical sample is sent to multiple laboratories which should analyse it under specified conditions. The round robin tests offer us the opportunity to identify factors which can affect the quality of our analyses in good time and discover possible errors – in the performance of analyses, for example.

We thus guarantee the impeccable quality and reliability of the analysis we perform for our customers.