KRAIBURG LEP – Leading Edge Protection

What is KRAIBURG LEP?

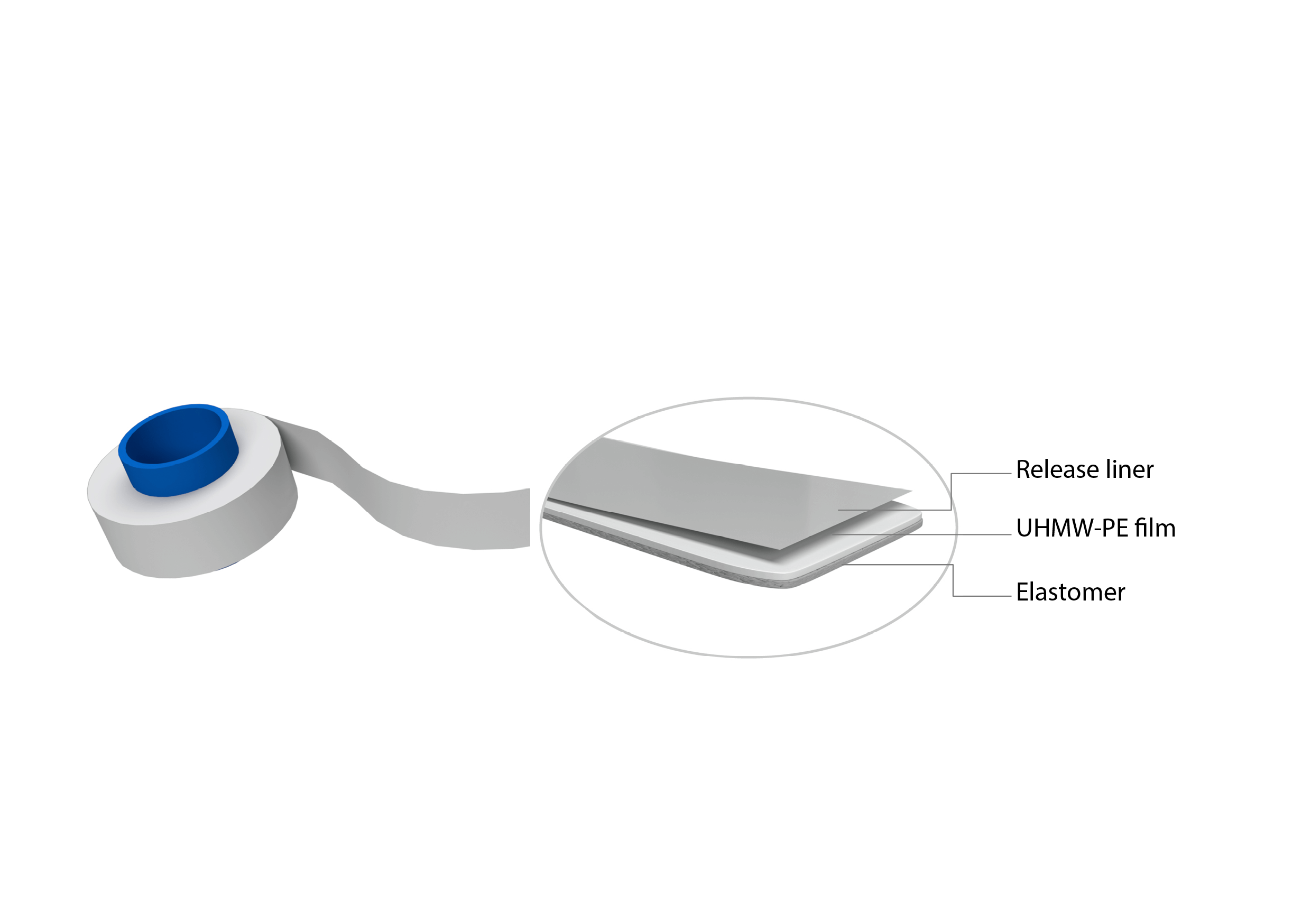

KRAIBURG LEP is a film for protection against erosion damage to the leading edges of the rotor blades of wind turbines. A quality product which has been developed over the past years and tailored to the requirements of an innovative, highly technical industry.

Sector and area of use: Wind power generation Onshore and Offshore

KRAIBURG LEP characterized by long-term erosion protection of the blade leading edge of wind turbines while at the same time offering UV protection of the erosion protection film and ease of use during application. The long-term reliability with a high dynamic durability results in low maintenance and repair costs for the plants. As our material is especially suitable for use in extreme conditions, customers benefit from KRAIBURG LEP in both onshore and offshore sectors.

Wind energy as a supporting pillar

The global targets for reducing CO2 emissions can only be achieved using green energy. Wind energy plays a key role here by using wind turbines. It now generates the greatest share of renewable energies and continues to grow constantly.

The efficient use of the natural force of wind using innovative technologies and systems is an exciting challenge for manufacturers, as well as for servicing and maintenance companies.

The long-term erosion protection for wind turbine rotor blades

The use of elastomers as a high-tech material has an important role. With KRAIBURG LEP, we offer a product which serves demanding applications and meets the challenges of an efficient production and application process for rotor blades.

What advantages does KRAIBURG LEP offer?

- High impact damping protects the underlaying layer of the laminate structure against impacts, e.g. by water drops or other particles

- Direct integration through resin infusion during rotor blade manufacture possible (no additional bonding agents required)

- Retroactive application using a suitable adhesive possible, e.g. when servicing the rotor blades

- Improved drainage of water drops thanks to low surface tension of the film

- Excellent UV resistance

What is the difference to existing solutions?

Impact resistance

Films which are available on the market allow the energy of the impacting rain to pass through on to the laminate unimpeded. Extensive tests using X-ray computer tomography show that damage to the fibre composite structure at the point of impact is significantly diminished by using KRAIBURG LEP.

Practical requirement - Partial repair

When developing KRAIBURG LEP, the focus was on practical requirements. Here, the option of partial repairs (splicing) was considered. In this context, a repair point with impact at an angle of 45° and 90° was tested. A ten-hour rain erosion simulation revealed no difference to the undamaged film. This confirms the high durability of KRAIBURG LEP.

Reduction of service and repair costs

The service intervals play a crucial role in the life cycle of a wind turbine. A damaged rotor blade surface results in poor performance which in turn results in loss of power output and high repair costs. The use of KRAIBURG LEP helps to reduce service and repair costs.